Copper busbar suppliers play an important role in the success of the PCB Bus project. In this blog, we will write vital information, including definitions, copper busbar applications, copper busbar suppliers, bus pcb bar boards, and how to choose a copper busbar supplier for PCB bus bar.

Do you complain about the following terrible headaches?

- Unstable supply chains and delayed delivery time?

- Concerned with different products that are lacking competitiveness in the Copper Busbar Market which is very romogenized?

- High pressure regarding cost control and increased efficiency?

The solution to overcome the problem is presented in the following sections.

- In collaboration with quality copper busbar suppliers, increasing shipping stability.

- Improve product performance and meet the needs of upper class customers with adjusted design, the use of new materials, such as copper core PCB, and thermal conductive layers.

- Optimizing procurement and supply chain management by making mass purchases to reduce costs.

Why are they called copper busbar?

Busbar is a conductor used to distribute electricity with low resistance. This is called a copper busbar when copper is the basic ingredient. Copper has a very good conductivity and mechanical strength, which makes it reliable for power distribution. In PCB design, copper bus rods are often used to carry large currents without overheating.

What is the relationship between copper busbar suppliers and PCB bar manufacturers?

There is a close relationship between copper busbar suppliers and PCB manufacturers. Suppliers provide raw copper strips, plates, or adjusted profiles. PCB manufacturers integrate this into the board, forming a bus stem PCB. Without strong cooperation, challenges such as incompatible material specifications, poor solder capabilities, or unstable mechanical suitability can occur. A trusted supplier relationship ensures consistent quality and predictable performance.

USA Copper Busbar Supplier

In the US, many copper busbar suppliers focus on adjusted shapes, coating, and machining appropriate. It supports industries such as filling EV, data centers, and renewable energy. When sources in the US, buyers often expect shorter waiting times and reliable certification such as UL and Rohs. PCB bus manufacturers benefit when this supplier provides stable logistics and material traction.

- Storm power component

Tennessee -based suppliers who offer a laminated, flexible, and isolated copper busbar with coating options such as tin, nickel, and silver. Certified for AS9100D. - Electric material (Elecmat)

Pennsylvania Company known as copper busbar with high purity, up to 20 feet long, serving the distribution of power, renewable energy, and the industrial sector. - Univertical

Indiana manufacturers with copper expertise for decades, providing ISO 9001 certified busbar for automotive electronics and high reliability.

In short, the power of the storm, electricity, and univertical give customers of a reliable certified busbar solution that is adjusted to demand PCB applications.

Australian copper busbar supplier

In Australia, copper busbar suppliers often serve the mining, energy and transportation industries. For PCB bus users, the challenge is to balance costs and quality. The imported material sometimes causes delay. Local suppliers help maintain fast responses and flexibility. For companies that build high PCB today, Australian sources provide more stability when the global supply chain faces disturbances.

- Metal and primary alloy

Supplying copper and strips that are free of oxygen, which is ideal for electricity and PCB applications. - James Coppell Lee (JCl Copper Reli Awer)

Suppliers aged a century in Victoria who offer bars and casting of copper alloys with fast turnover. - Fulton Industry

Providing a flat copper canal in a length of 4 meters, widely used in industrial and electricity projects.

In short, primary metals, JCL, and Fulton Industries stand out in Australia due to fast service and high -quality copper busbar solutions.

What is the function of the copper busbar material for the high PCB bus bar today?

Copper busbar material in the high PCB bus bar currently performs three main roles: conducting electricity, managing heat, and supporting mechanical strength. The conductivity reduces power loss. Thermal properties protect sensitive components. The solid form strengthens the PCB when large currents flow. Choosing the wrong copper level can increase resistance and cause overheating, so the right selection is very important.

What is the copper bus bar used for?

Copper bus bar is widely used in automotive power modules, EV battery systems, solar inverters, industrial machines, and aerospace systems. In the integration of PCB, they simplify the current stomach at this time while reducing board space. By implanting a copper bus stem into the PCB, engineers reach a concise layout and lower resistance compared to wide copper traces.

How do I choose a copper busbar supplier for the bus pcb bar?

When choosing a supplier, consider these steps:

- Check the purity of copper and coating options such as tin -coated copper bus bar for oxidation resistance.

- Review the accuracy and mechanical tolerance to avoid incompatibility during PCB assembly.

- Compare ampacity data using a Copper Busbar Ampacity Calc with your design.

- Evaluate supplier certification and testing capabilities.

- Ask about the stability of delivery and scope of global supply.

By applying these steps, engineers reduce the risk in the current high PCB project and achieve reliable results.

What is the Bus PCB Bus Bus application?

The bus bar PCB board is applied in power conversion, battery package, industrial controller, and high -speed data system. It combines copper busbar with FR4, metal core, or ceramic substrate. This design allows high high current paths. Applications expand the filling of EV, 5G equipment, aerospace modules, and telecommunications base stations where stable power is very important.

Why choose the best technology for PCB Fabrication Copper Bus Bus?

Many customers face pain points such as unstable bus supply, long waiting times, or weak engineering support. The best technology discusses it with professional material sources, strict quality control, and sophisticated production paths.

- Certified under ISO 9001, ISO 13485, IATF 16949, and AS9100D, we ensure that each PCB copper bus bar meets demanding industrial standards.

- Our MES system supports traction for each batch, which built a reliable and high quality PCB for our customers.

- By working with strong copper busbar suppliers throughout the world, we reduce the risk and improve the performance and stability of shipping. Having a stable supply chain provides competitive advantage in the control of costs and waiting time.

- We have the ability to customize for various needs of your copper PCB bus. We know the needs of upper class products are increasing, and please feel confident that we have a professional technical team, sophisticated production paths, and sufficient technical capabilities to meet your high quality needs. So you can’t worry about severe product problems.

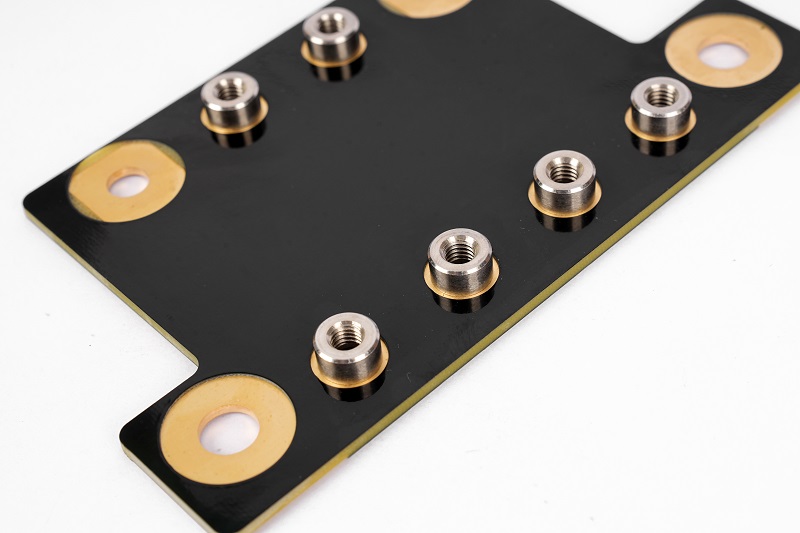

Cases of pcb bus bar in the best technology

We have provided PCB Bus Power Bus in a power battery for our customers. Here is a picture of our PCB bus blades used in power batteries.

As for advancing new energy and the energy storage industry, the requirements for fluctuations in power pressure and thermal discipline are tighter. Because the power density of resources and batteries is increasingly optimized. Choosing a copper busbar supplier to provide copper busbar material for the manufacture of PCB copper busbar is very important.

In short, the supplier of copper busbar takes a central role in the PCB project embedded by Busbar. Make an understanding of the supplier of copper busbar and understand knowledge about how to choose it will make your difference in front with the PCB project. Warm welcome to work with the best technology, we can provide quality PCB bus bus and full engineering support. We solve the risk of supply chains and improve the final performance of the PCB at this time. Please contact us via [email protected] To get an offer for the PCB bus bar.

Tag: Copper Busbar Supplier

This entry was posted on Thursday, August 28, 2025 at 17:51 and submitted under the best PCB, BestTPCB, Special PCB. You can follow any response to this entry through RSS 2.0 bait. You can jump to the end and leave a response. Pinging is currently not permitted.

News

Berita

News Flash

Blog

Technology

Sports

Sport

Football

Tips

Finance

Berita Terkini

Berita Terbaru

Berita Kekinian

News

Berita Terkini

Olahraga

Pasang Internet Myrepublic

Jasa Import China

Jasa Import Door to Door

Pendidikan